Pretoria-based Redeployable Camp Systems South Africa (RCSSA), part of the Canvas and Tent Group, has finished supplying tents to the South African National Defence Force (SANDF) as part of Project Swatch for a new Transportable Camp System.

RCSSA has completed its portion of the project, which entailed the supply of canvas products and providing operational support for them.

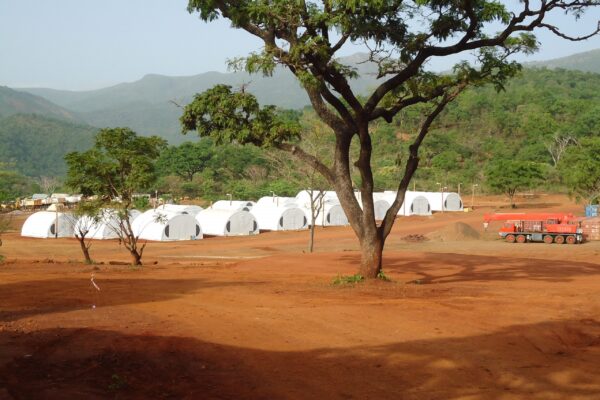

According to RCSSA’s group marketing manager Karen Coetzer, the canvas products consisted of small, medium and large accommodation tents constructed of a modular barrel shaped steel. The tents are covered by a durable, flame-retardant PVC fabric barrel cover.

“We also supplied vehicle tents for daily parking and execution of vehicle maintenance and repair tasks,” she explained. “The products were packed in specially developed steel crates for ease of deployment.”

She added that the crates are all packed in six metre ISO shipping containers that serve a dual role for storage and transportation. This also allows the consignment to fit into C-130 Hercules aircraft for air transportability.

The Canvas Products accommodation tents are supplied complete with solid doors, interlocking rubber floor tiles for a raised floor, furniture and support equipment. Accommodation tents has the option to be constructed on a prepared surface such directly on the ground or on a raised floor. Raised floors consisting of steel beams, jacks for levelling and wood inserts were supplied as part of canvas products

“As with all modular systems that we provide, the mess tent power distribution is essentially ‘plug-and-play’”, Coetzer said. “Electrical distribution boards are pre-assembled and electricity is distributed via harnesses to power outlets and connectors. High quality and reliable LED lighting is utilised throughout the facility.”

A trolley with capacity of 1.5 tons was developed by RCSSA to move crates and tent components from the container storage to the construction area. Several trailers may be linked together to form a train to be pulled by a vehicle at speed not exceeding 20 km/h.

(The trailers are not suitable for public road application). A hand-operated hydraulic stacker is also provided.

Project Swatch was completed by Armscor late last year. Designed to supply expandable field accommodation and related items including ablution, storage of goods ranging from ammunition through to rations and medical supplies, the project first saw the light of day in 2001.

The focus of Swatch is to provide transportable – and durable – “camping systems” for use in deployments less than eight weeks long.

The system utilises canvas tented products, expandable containers for water storage, ablution and laundry use; waste management; cooling and storage as well as offices for clerks, paymasters and other administrative functions.

In addition to showers, basins and toilets, the ablution component is fitted with holding cells for military justice system offenders ahead of court appearances or transfers to other holding facilities.

“The new system,” SA Soldier writes, “recognises the hardship of deployment and the difficulty operational soldiers experience trying to keep neat and tidy. The new system helps transcend the physical and environmental challenges of deployment, allowing soldiers to operate effectively at all times with limited disturbance – especially in countries such as Democratic Republic of Congo (DRC) and Sudan”.

Originally published on Defencenet.co.za on 17 January 2022

Recent Comments